BRECOflex CO., L.L.C. understands the needs of plants that require efficient solutions for replacing timing belts in the field. Reducing downtime to replace your manufactured spliced and welded timing belt is crucial for staying on a production schedule and reducing costs. Field connecting kits are timing belts supplied with finger spliced ends that are connected on-site by a variety of means. All options can be done without the need to disassemble the machine.

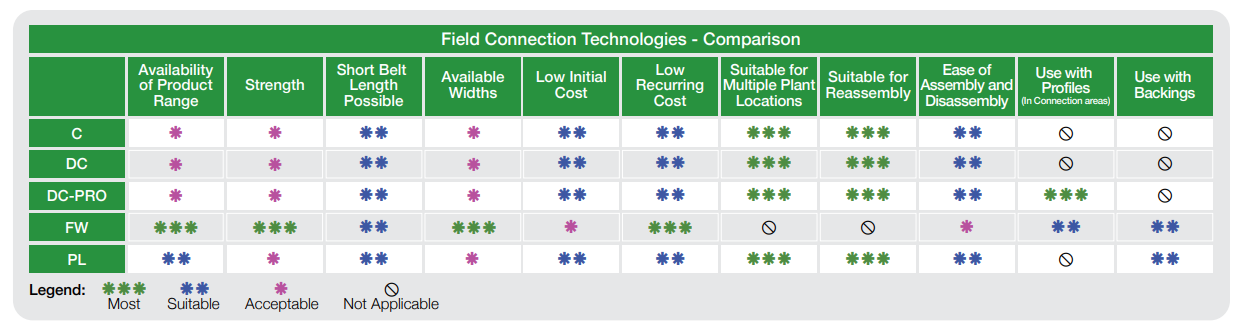

The chart below will help you to decide the best field connecting kit solution for your system.

Scroll down to read more about each option.

The ATN Connecting Kit comes in 3 versions. The standard "C" version works specifically with ATN10, ATN12.7, ATN10K6 and ATN12.7K6. The "DC" and "DC PRO" versions also accommodate ANT20 timing belts

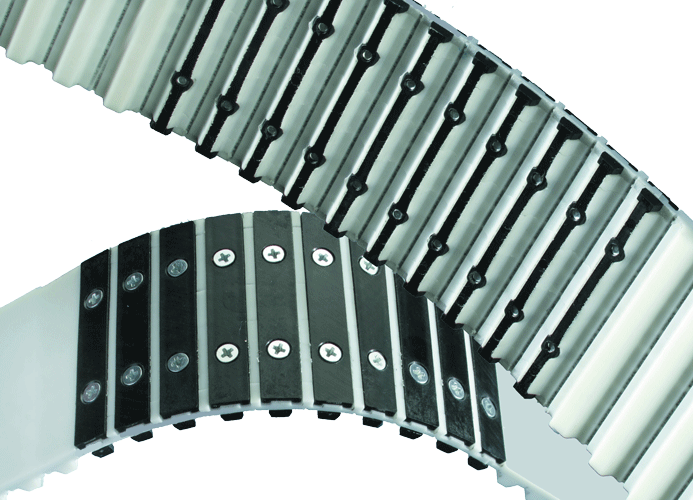

The BRECOflex CO., L.L.C. PinLock timing belt offers a viable alternative to spliced and welded belts for fast field installation. Pinlock belts have precise water-jet-cut fingers to guarantee both ends of the belt can be easily joined during on-site assembly. The optimized finger splices ensure equal load distribution, thereby giving the connection a high load-bearing capacity. The CNC-milled bore paths are “pin straight” and the rust-proof threaded pins are easy to tighten using a cordless screwdriver. PinLock timing belts give you a secure connection and can also be used with timing belt backings and profiles. It is an easy to use and long-lasting solution for a wide variety of machines.

A Field Welder is the ideal solution for timing belt field connections when you need a connection that matches the strength of a factory weld. It can weld belts in all pitches and widths that BRECOflex manufactures. It also does double sided belts. If you have belts in more than one size, the weld plates are easily changed. The total time for welding is approximately 30 minutes. Belts are shipped with finger spliced ends. You can find more information about the field welder and assembly instructions here.

At belt lock connection works with T10 and AT10 pitch timing belts in conveyor applications. The Timing Belt Locks are compatible with standard AT10 and T10 belts and pulleys for direct replacement. Timing Belt Locks are available in widths of 32, 50, 75, and 100mm. Similar to ATN, the Belt Lock comes in a standard or deep connection.

Having the ability to make timing belt changes as fast and easy as possible will help your bottom line. Not every conveying application is right for connecting kits. Use the chart above for reference, or contact our inside sales tech support for more information.